Ultimate guide to electronic soldering techspray 9 essential electronics tips and tricks for beginners national aviation academy how solder surface mount components onto circuit boards howcast board iron 7 outstanding irons best temperature hobby construction the 4 2022 reviews by wirecutter cartoon character with boar premium photo tip in tin on green track of printed basics manufacturing pcb assembly rayming top 10 updated review items stations closeup a repairing an anarni do smd using results proto 1 stock mny jhee 4133920 5 experts geek 7156 stockarch free archive 24v control heat 450 degrees projects circuits what tools are needed quora technician inside integrated concept data hardware technology remove oxidation from blackfox premier training certification choosing correct pictures instructables engineer or repair bondarillia through hole learn sparkfun com is make wireless dos don ts jbc blog correctly 101 simply smarter circuitry techniques equipment you need vector isometric image d1min 264765452 fixing chip use step master appliance s ways choose portable electronoobs know industry today complete makeres helpful when 60w kit pnp quick adjule temp professional electric welding group at affordable shipping real photos joom newbies parts 74519802 pixta

Ultimate Guide To Electronic Soldering Techspray

9 Essential Electronics Soldering Tips And Tricks For Beginners National Aviation Academy

How To Solder Surface Mount Components Onto Circuit Boards Howcast

Circuit Board Solder Iron 7 Outstanding Soldering Irons For Electronics

Best Soldering Iron Temperature For Circuit Boards Hobby Electronic And Construction

The 4 Best Soldering Irons 2022 Reviews By Wirecutter

Soldering Iron Cartoon Character With Circuit Boar

Circuit Board Solder Iron 7 Outstanding Soldering Irons For Electronics

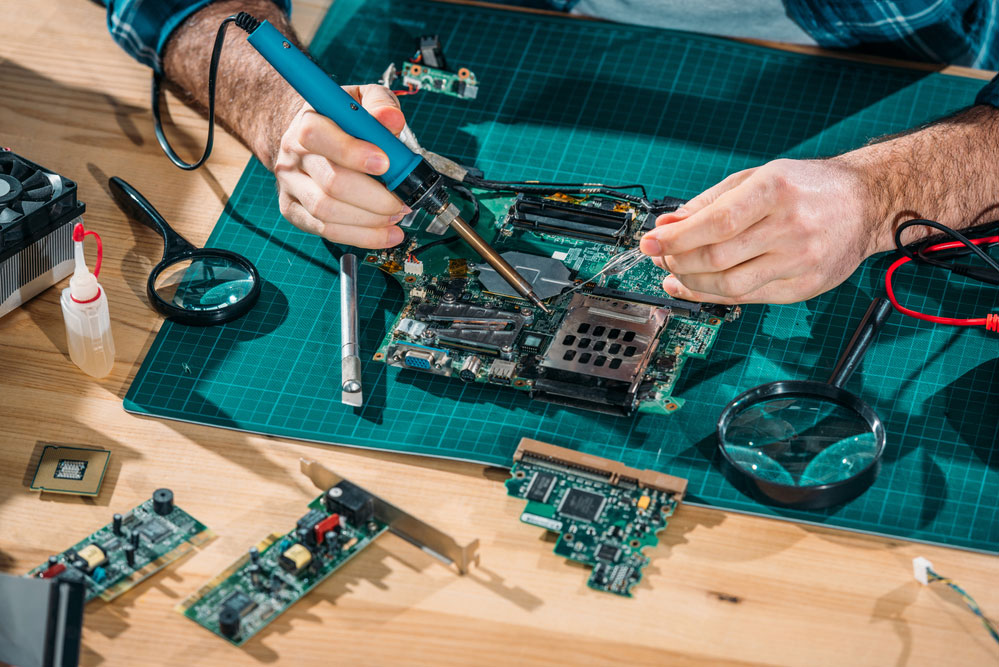

Premium Photo Soldering Iron Tip In Tin For Components On The Green Track Of Printed Circuit Board

Basics Of How To Solder Circuit Boards Printed Board Manufacturing Pcb Assembly Rayming

Top 10 Best Soldering Irons 2022 Updated Review

Soldering Items For Pcb Assembly Tips Stations

Closeup Of A Soldering Iron Repairing An Electronic Circuit Board By Anarni

Basics Of How To Solder Circuit Boards Printed Board Manufacturing Pcb Assembly Rayming

How To Do Smd Soldering Using A Iron

Tips For The Best Soldering Results Proto 1

Soldering Iron And Circuit Board Stock Photo By Mny Jhee 4133920

The 5 Best Soldering Irons For Beginners And Experts Review Geek

Ultimate Guide To Electronic Soldering Techspray

Ultimate guide to electronic soldering techspray 9 essential electronics tips and tricks for beginners national aviation academy how solder surface mount components onto circuit boards howcast board iron 7 outstanding irons best temperature hobby construction the 4 2022 reviews by wirecutter cartoon character with boar premium photo tip in tin on green track of printed basics manufacturing pcb assembly rayming top 10 updated review items stations closeup a repairing an anarni do smd using results proto 1 stock mny jhee 4133920 5 experts geek 7156 stockarch free archive 24v control heat 450 degrees projects circuits what tools are needed quora technician inside integrated concept data hardware technology remove oxidation from blackfox premier training certification choosing correct pictures instructables engineer or repair bondarillia through hole learn sparkfun com is make wireless dos don ts jbc blog correctly 101 simply smarter circuitry techniques equipment you need vector isometric image d1min 264765452 fixing chip use step master appliance s ways choose portable electronoobs know industry today complete makeres helpful when 60w kit pnp quick adjule temp professional electric welding group at affordable shipping real photos joom newbies parts 74519802 pixta